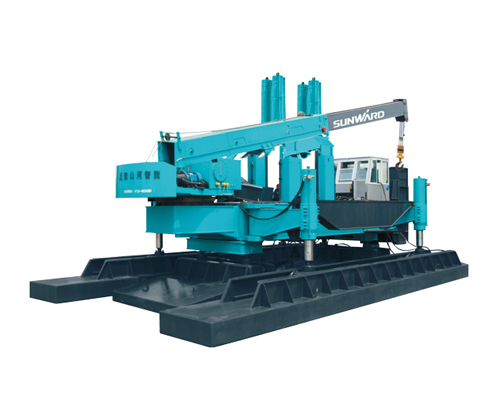

Piling mobile static indentation machine contains in its design: load frame, guide columns with pressing and clamping mechanisms placed on them, hydraulic cylinders for working and return travel, crane installation, as well as controls. The pile-pressing unit is anchored with metal weights (counterweights). In addition to the central columns, the unit has side columns, when moving the working equipment onto which the unit can press piles next to existing walls or other obstacles with a force of up to 70% of the nominal. Hydraulic cylinders are manufactured using REXROTH technology using Japanese MOK seals.

The scheme of the installation is simple - first, 2 hydraulic cylinders push the pile several meters at maximum speed, then all 4 cylinders work to increase the force. The pile pressing unit provides high accuracy of pile driving and continuous control of the pressing force, which is important for assessing the bearing capacity of the pile during the driving process. The control of the indentation force allows you to optimize the design load and the number of piles in the project and, while ensuring the specified bearing capacity, to minimize the costs of building the foundation.

Pile-pressing installations are easy to operate, have a relatively low weight and overall dimensions, are transported disassembled on large-sized automobile platforms (trawls) for transporting construction equipment or on railway platforms. The use of hydraulic pile-pressing installations is effective in spot construction, due to its higher productivity compared to the percussion method of driving piles, eliminating the destruction of pile heads, increasing the accuracy and reducing the energy consumption of their driving, the ability to measure the bearing capacity of each submerged pile, and improving working conditions.

|